QUALITY ASSURANCE

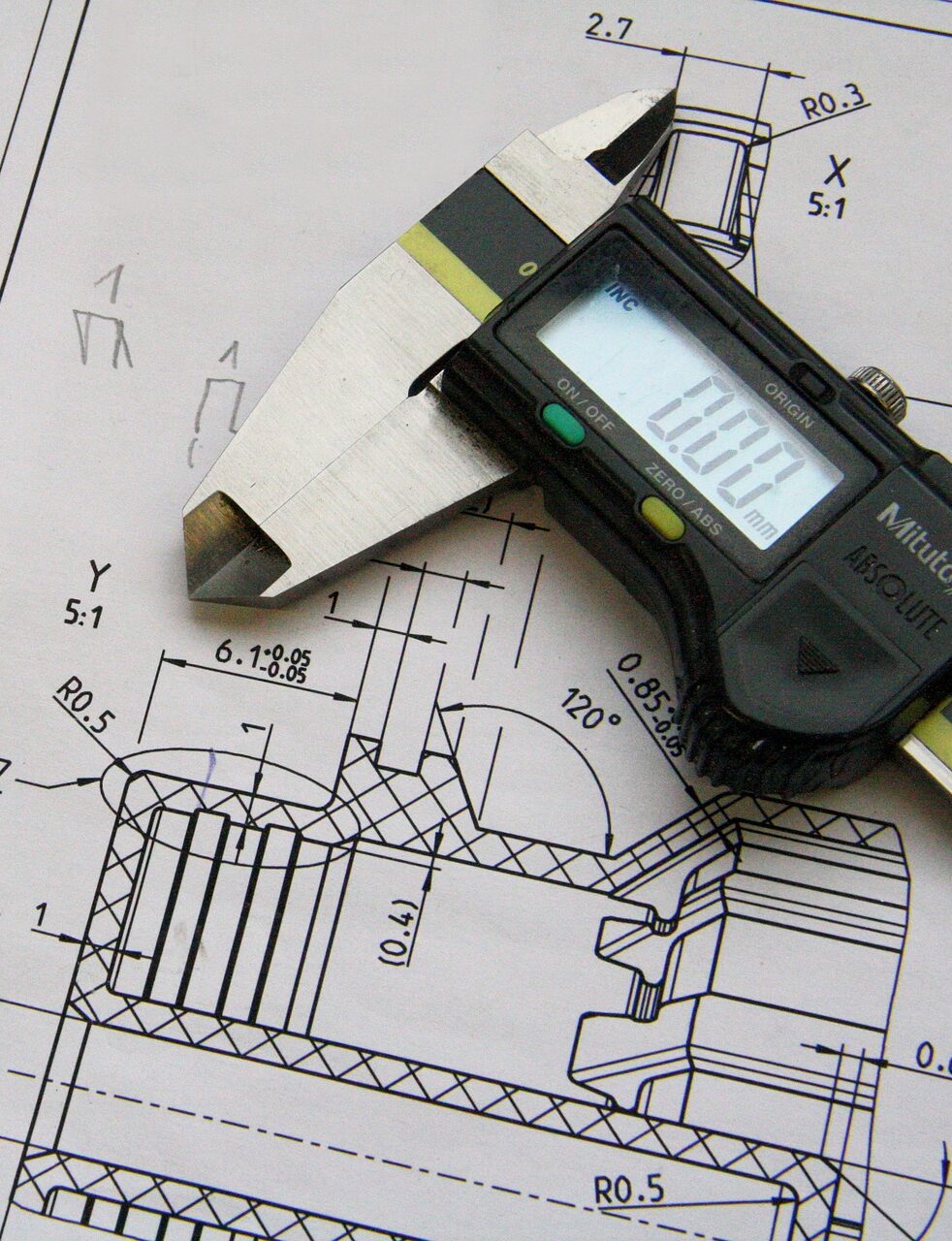

DAM understands the critical nature of our product applications and maintains a rigorous Quality Management System (QMS) and quality control practices. Our QMS allows us to ensure that every product manufactured meets customers’ specification and expectations. We adhere to specific procedure and protocols which meet AS9100 and ISO9001 standards. Traceability is maintained under robust documentation practices for raw materials, hardware, machining processes, outside processes, assembly and all other critical services. It is then electronically stored for every production run, no matter the quantity. We have extensive inspection capabilities to ensure that your final product complies with all drawing and contractual requirements.

AS9100 D COMPLIANT

ISO9005:2015 CERTIFIED

QUALITY POLICY

Defense and Aerospace Manufacturing is committed to delivering quality services that meet or exceed our customers’ expectations, including applicable legal requirements, and focusing on continued improvement in our processes. We accomplish this by monitoring our performance against our established objectives, identifying areas where we can improve our QMS and its processes, and through management commitment and employee training.

INSPECTION EQUIPMENT

All inspection equipment is traceable to SI through the National Institute of Standards and Technology (NIST) and/or recognized national or international standards laboratories. All equipment is certified and in compliance with ANSI/NCSL Z540

CALIPERS

SURFACE PLATES

INDICATORS

PIN GAGES

THREAD GAGES

COMPARATOR

HEIGHT GAGES

MICROMETERS

GAUGE BLOCKS

bore gage

PROFILOMETERS

CMM

Contact us

Get in touch

Address:

11346 Sunco Dr #104,

Rancho Cordova, CA 95742

Phone:

+1 (916) 661-6530

Email:

rfq@damfg.com